The latest news, trends, analysis, interviews and podcasts from the global food and beverage industry

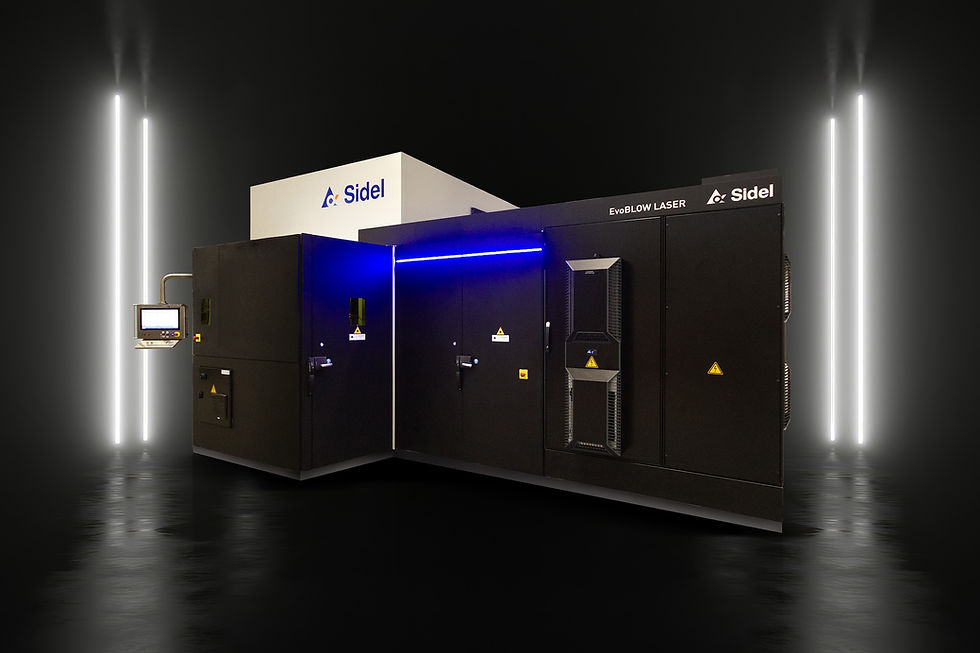

Sidel will launch its EvoBlow Laser technology during Drinktec 2025, taking place from September 15-19 at the Munich Trade Fair Centre.

This technology promises to enhance efficiency, sustainability and design flexibility in the production of PET and recycled PET (rPET) packaging.

Sidel’s president and CEO, Pietro Cassani, commented: “Sidel has led the way in blowing technology for over 45 years. The EvoBlow Laser is a game-changer that will reshape the industry again, setting a new standard for line efficiency and opening new lightweighting possibilities.”

Historically, halogen technology has dominated the PET packaging market, but its limitations have become increasingly apparent. EvoBlow Laser addresses these challenges by employing precision heating through up to 36 heating lines, compared to the eight zones used in traditional methods.

This increased control allows for the production of lighter yet stronger containers, a feat achieved through the creation of invisible ‘power rings’ that enhance structural integrity without adding material.

The EvoBlow Laser's ability to deliver consistent quality is particularly noteworthy. Unlike halogen solutions, which are sensitive to environmental conditions, the laser technology operates independently, ensuring uniform results across all production runs.

This stability not only streamlines operations but also reduces the need for frequent adjustments, thereby enhancing overall productivity.

The EvoBlow Laser technology is designed to meet the growing demands for cost reduction and sustainability in production. Its cold start capability eliminates downtime, allowing for immediate readiness and reducing the need for standby modes.

Additionally, live speed modulation enables real-time adjustments to production speeds, further optimising line efficiency.

From a sustainability perspective, the EvoBlow Laser supports increased use of rPET, as it is less sensitive to material variations.

The technology also significantly reduces preform waste by up to 50% compared to traditional solutions, highlighting its potential to make packaging processes more environmentally friendly.

The technology has already gained traction through rigorous field testing in collaboration with Refresco.

Coert Michielsen, chief supply chain officer at Refresco, said: “After 45 years of halogen technology, we are now entering a new era. I firmly believe that laser oven technology will become the new standard.”