The latest news, trends, analysis, interviews and podcasts from the global food and beverage industry

Last month, FoodBev Media’s editorial director, SiânYates, embarked on an expedition to Côte d'Ivoire in West Africa, under the guidance of Olam Food Ingredients’ (Ofi) sustainability team. Travelling across continents, she explored the intricate network of farms and processing facilities related to commodities like cashews, coffee and cocoa. Siân observed Ofi's dedication to ethical practices and sustainability, unravelling the epic journey these commodities undertake, from farm to table. Join Siân as she recounts her trip and sheds light on the captivating narratives behind each ingredient's journey.

Day one – UK > Amsterdam

After a short plane ride from Bristol, our journey begins in the Netherlands, at Ofi’s customer solutions centre in Amsterdam’s The Joan building.

The Joan itself is quite remarkable – designed with the goal of “shaking the neighbourhood up a bit". The building boasts green credentials, featuring vertical gardens on every floor, 804 solar panels and rainwater collection for plants. Upon entering, it becomes evident what Ofi’s mission is all about: driving transformation in the food ingredient industry while upholding the principles of sustainability, ethics and social responsibility.

The centre serves as a cornerstone of Ofi’s innovation capabilities, dedicated to delivering cutting-edge food and beverage ingredient solutions to its European customer base.

Ofi has divided its offerings into five ingredients/materials platforms: cocoa, coffee, dairy, spices and nuts. Within these groups, applications include chocolate and confectionery; plant-based; savoury and culinary; snacking; beverage; and dairy and desserts. Each category has a dedicated laboratory space at the centre.

1 in 5 chocolate bars globally contains Ofi’s products, and the company's beans are featured in 90 billion cups of coffee annually

Top trends

During an introductory presentation, Ofi’s Zizi Waxa told us more about some of the trends shaping Ofi’s work, and the wider food and beverage industry at present. These include:

Redefining Value: how sustainability has evolved from being an overarching trend to becoming a codified value proposition in F&B

Generational Push: the nuances in preferences between different age groups and implications for the F&B sector

Plant-Based: leveraging ingredients and technology to improve flavour and texture, which are both barriers to adoption

Farming the Future: how consumers have become more informed about the environmental impact of the food system and want to manage their impact on the environment

Unpuzzling Health: consumers are increasingly employing diet-based health management strategies, reflecting the importance of communication and certification on-pack to demystify health choices

Revenge Spending: as disposable incomes increasingly come under pressure, consumers are willing to pay a premium for occasional treats, rather than big spends such as holidays

Lab space

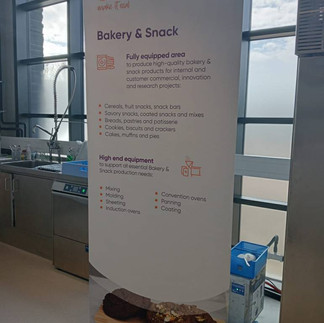

Each lab at the centre is dedicated to one of Ofi’s application groups. For instance, in the 'Bakery and Snacks' lab, the team is equipped to handle both internal and commercial projects. Products include cereals, fruit snacks, snack bars, savoury snacks and mixes, breads, pastries, crackers, cakes, muffins and pies. Equipment can facilitate mixing, molding, sheeting, panning and coating, and includes induction and convection ovens.

Meanwhile, the 'Beverages, Desserts and Ice Cream' lab focuses on UHT dairy and plant-based beverages, dry blends (such as cocoa powder beverages), yogurt and fermented products, ice cream and frozen novelties, as well as desserts like pudding and mousse. Process equipment includes HTST/UHT systems, high-pressure homogenizers, water baths for mixing, pasteurisation, fermentation and ageing, laminar flow systems for sterile filling, artisanal and soft-serve ice cream makers, industrial and blast freezers, dry blending machines, and ULT freezers for cultures.

The 'Sensory and Analytics' lab has sensory booths for focus groups, a discussion room for training and agreement on descriptive analysis, adjustable lights to avoid colour and light bias, and booths customised for specific ingredients like cocoa and chocolate. Additionally, there's a separate preparation area to prevent odours and other distractions.

A huge thank you to the Ofi Amsterdam team for the tour, and for all the tasty samples! Chef Talia Profet, Carin Gerzon, Pilar Darre, Zizi Waxa, Katherine Durrell. Next stop: Côte d'Ivoire!

Ofi stats

-Operating in 50 countries -$11.6 billion in revenue -20,000+ employees -110+ manufacturing facilities -15 innovation centres -Sourcing from 2.4 million farmers

Day 2: Côte d'Ivoire, Abidjan

Despite arriving at the hotel around 4:30am, the excitement for our anticipated adventure in this West African coastal country kept me going. Today, we visited Anyama cashew processing facility in Abidjan city.

Cashing in on cashew

Flora Coffi, Ofi’s head of sustainability for Africa, introduced us to the company’s cashew operations. She told us that, over the past decade, Côte d’Ivoire has seen a remarkable expansion in its cashew crop, soaring to 700,000 metric tonnes and solidifying its position as Africa's leading producer and exporter of cashews. The country stands as one of the largest contributors to organic and Fairtrade cashew kernels globally.

Most cashews are exported from Africa to the US, Europe and Asia, totalling approx. 1.2 million tonnes each year. Coffi explained that while Côte d'Ivoire produces an impressive volume of cashews annually, the nut is not a prevalent component of the consumer diet in Africa, possibly due to its high retail costs.

For its cashew nut efforts, Ofi boasts a vast network of over 35,500 partner farmers and 200 traders. 31,000 of these partners benefit from its sustainability initiatives. Its infrastructure spans three processing facilities situated in Bouaké, Dimbokro and Djekanou, providing employment opportunities for over 4,000 individuals, with more than 70% being women.

In a nutshell

Cashew in Côte d’Ivoire Crop: 1.2 million mT (22/23 crop) Position: World’s top producer of raw cashew nuts

Ofi in Côte d’Ivoire Activities: Cashew origination, handling, export and shelling Market position: First buyer and sheller Infrastructure: 8 nut handling and warehousing facilities, 4 processing facilities Employee base: 225 permanent, up to 3,000 temporary Partners: Approx. 100,000 farmers and licensed buying agents

Facility tour

It is unlikely consumers stop to think about the incredible journey the small cashew nut goes on prior to reaching their end products. Here’s a run-down of that journey, as explained to us by the Ofi team during the facility tour.

Once the cashew nut has been farmed, harvested and separated from the false fruit (this we will see tomorrow), it is then transported to the processing facility. As processing commences, the raw cashews are removed from the warehouse for heat treatment, where they are heated to 180°C. Typically, steam is used to soften the tough shell before de-shelling. Subsequently, the steamed cashews are left to air dry.

The extraction of the kidney bean-shaped cashew nut from its shell is the most intricate processing stage. Upon cracking the shell, a highly corrosive oil known as CNSL, or 'cashew nutshell liquid,' is released. Exposure to this oil can result in skin burns and sores, posing notable health hazards to workers. The handling of this ingredient requires skilled staff and all Ofi employees are trained to deal with such materials.

During de-shelling, the leftover cashew shells are not simply discarded; instead, they are repurposed by various companies to produce oil or paint. Furthermore, a portion of the shells is retained and utilised as fuel in a boiler to generate energy, ensuring a sustainable process overall.

Large machines with curved blades split the hard shell of the nut in a single motion, mimicking its natural curvature. Due to the variation in shell size and shape, there is no universal blade design, which can result in a significant number of broken kernels or kernels contaminated with CNSL.

So long as the nuts are safe to consume, however, there is a place for them at Anyama. Prashant Kilawat, head of this cashew processing facility, explained the unique characteristics of each cashew. He says that the nut undergoes a grading process based on factors such as colour, quality, size and shape, which directly influences pricing.

Larger, intact cashews are deemed premium, whereas smaller or broken ones – those suitable for garnishing stir-fries or incorporating into confectionery and snack bars, for example – are priced more affordably. This method enables Ofi to cater to a diverse market, meeting the varied needs of its customers. Typical applications for these cashews include snacks and mixes, alternative dairy products, confectionery and protein powders.

Once the kernel reaches a peelable condition, it is sent through machines using air pressure and friction to remove the testa layer.

After peeling, cashews are sorted based on size, shape and colour using sorters and optical machinery. However, human inspection remains unparalleled, thus a final round of manual grading concludes the process. The Ofi inspection team is made up of many women who have been trained to identify cashews that do not meet the company’s standards.

Every woman undertakes an eight-hour shift, punctuated by a brief 30-minute lunch break. The pace of their sorting is remarkable! They work with astonishing speed, swiftly peeling away any excess debris as needed, while detecting rot/black spots and for the correct size, colour, shape and other qualities.

At this facility, Ofi can produce 12,000mT of cashews annually.

Bahkan deni

Our final stop on the tour is Bahkan Deni, the cashew facility’s daycare centre for children aged 1-4. Here, both women and men employed at the plant can bring their young ones, ensuring continuous care for their families. Coffi said that this facility is an integral part of the company's 'Healthy Living' initiative, which prioritises its workforce.

In addition to providing childcare, this initiative seeks to enhance the lives of its employees and their communities by addressing nutritional challenges such as iron intake and supplements, as well as health issues like vaccines and preventive measures against illnesses.

A moment of reflection

As we made our way back to the hotel, I found myself reflecting on something Coffi had shared earlier in the day – that the average life expectancy in Côte d'Ivoire is 62.9 years old. In stark contrast, the average life expectancy in the UK stands at 81 years (according to the World Bank). This jarring juxtaposition casts a sobering shadow. The comforts of home felt distant, and I found myself confronted with the disparities that exist globally. It was a poignant reminder of the privileged bubble many of us live in.

Despite some of the concerns you read about – the media’s report of travelling to the Côte d'Ivoire is one of danger, disease and caution – I felt much joy and kindness from the Ofi team, the factory workers and the local community. Everywhere I turned, there was an unmistakable sense of togetherness, a community spirit that made me reflect on the invaluable lessons we could glean about the importance of connection.

Day 3: Yamoussoukro > Soubre > San-Pédro

Day three began with a scenic journey, as we embarked on a four-hour drive through the country towards the savannah and capital city, Yamoussoukro. While a lengthy car ride may prompt an eye roll, I've always found them to be an enriching way to see a country, especially when time is limited. As we traversed the roads, I couldn't help but notice the varying conditions, with some stretches marred by potholes and ditches. A huge thank you to our skilled drivers for deftly navigating these obstacles! Côte d'Ivoire boasts lush rainforests, with thick, dense expanses of jungle stretching as far as the eye can see, painting the landscape in vibrant shades of green. This verdant beauty stands in stark contrast to the arid desert and savannah terrain that surrounds it, and the mud-coloured huts that line the roads. While Abidjan serves as the bustling economic hub and the country's largest city, Yamoussoukro exudes a quieter, more traditional charm. It is here that one finds the awe-inspiring Basilica of Our Lady of Peace, proudly holding the title of the world's largest basilica.

On the farm

Nestled on the outskirts of Yamoussoukro lies one cashew farm that plays a crucial role in delivering this prized commodity to consumers across the US, Europe and Asia. Today's temperature peaked at about 38 degrees, making the welcoming shade of the mature cashew trees a relief. Cashew harvesting typically occurs between February and April, extending sometimes until June. Prior to the start of the season, farmers and their working communities undergo comprehensive training on nurturing and safeguarding these valuable crops. They are also trained in dealing with wildfires, a more regular occurrence in the country in recent years. To join the Ofi family, cashew farms must meet stringent criteria: they must employ a significant number of women and ensure that families prioritise education by sending their children to school. Additionally, of course, rigorous measures are in place to prevent any form of child or forced labour, ensuring ethical practices across the board.

Furthermore, adherence to organic farming practices is imperative for inclusion within the Ofi network. Cashew farmer Harounan Sangaré highlighted that, despite the detrimental effects of fertilisers and insecticides on tree health, some farmers remain reluctant to relinquish their use. However, the Ofi team said there was a noteworthy shift in mindset among certain farmers who have recently joined the cooperative, which stems from witnessing the positive outcomes of embracing organic farming techniques.

These methods encompass pruning to eradicate unwanted vegetation and reduce disease incidence, careful removal of new branches that could hinder the growth of others, and prompt collection of fallen fruit (within three days) to maintain freshness and quality.

Once ripe, the cashew nut is carefully separated from the fruit and left to dry on mats laid out on the ground. After the drying process, the nuts are carefully stored in cloth bags in local households to preserve their quality. It's worth noting that a single mature cashew tree can yield approximately 1 metric tonne of cashews.

The cashew fruit, referred to as the ‘apple,’ is edible. In certain regions, companies gather the fruit to produce juice, a beverage that is particularly popular in South American countries like Brazil. Some regions deep fry it, while others use it to produce liquor. Moreover, it can be enjoyed fresh as a standalone treat, incorporated into savoury dishes such as curries, or even fermented to produce vinegar and citric acid.

Spacing plays a crucial role in cashew farming. As Sangaré pointed out, some farmers overcrowd their plots in hopes of maximising yields. However, he explained, too many trees on one plot can diminish productivity. Optimal spacing ensures each tree receives sufficient water, sunlight and nutrients to thrive. At this farm, there are about 100 trees per hectare (the ideal amount), showcasing the potential for substantial harvests. Surprisingly, the farmers here have observed a positive effect of climate change on cashew harvesting. They said the increased heat associated with global warming has benefited production. Cashew trees thrive in warm climates and struggle in rainy or cold conditions. The drought and heat have led to improved yields!

The typical lifespan of a cashew tree is ten years, with its peak production period lasting around five-six years.

From bean to cup

Our next stop was a coffee farm in Sourbre. We were greeted by the local community, and by Ofi’s coffee sustainability regional representative, Dorcas Yao, and coffee farmer, Yameogo Isiaka. The three pillars of Ofi’s coffee farming, Isiaka said, are production, protection and inclusion.

Reforestation stands as a cornerstone in Ofi's commitment to sustainable farming practices. Central to this effort is the planting of shade or shelter trees amid the coffee plants. These trees play a vital role in regulating temperature, conserving moisture and shielding crops from adverse weather conditions.

Furthermore, the shade trees mitigate soil erosion, foster biodiversity and aid in natural pest control. By creating an optimal environment, shade trees not only enhance crop yields but also bolster resilience against environmental pressures, thereby advancing sustainable agricultural practices.

Once the coffee plants reach 18 months of age, farms can commence bean picking, typically during the harvest season spanning from September to December. However, unlike the cashew, the impact of climate change on coffee cultivation is not as favourable. Farmers in this region have faced significant challenges, including the loss of smaller trees due to prolonged drought conditions. The area had experienced a severe lack of rainfall over the past four months, exacerbating the difficulties faced by coffee growers.

As a result of the volatile nature of the commodity market, the community supplements any income it may lose through various alternative employment opportunities to ensure financial stability. Ofi plays a pivotal role in supporting these communities by facilitating diverse employment activities, such as establishing shops, soap making, providing training in tailoring, engaging in cassava farming, and imparting essential business management skills such as bookkeeping.

It's improbable that the coffee produced here will find its way to your cup served by a local artisanal barista. Robusta coffee, commonly cultivated in this region, is typically reserved for private-label brands used in instant or freeze-dried coffee products. While robusta has its uses, its quality doesn't quite match the premium standards often associated with speciality coffees – these tend to be produced in regions with high altitudes, like Vietnam, Colombia, Brazil and Costa Rica.

Tomorrow, we'll be completing the trio of the three C's: cashew (check), coffee (check), and finally, cocoa.

Day 4: Gagny & Gagny Village

Today, we ventured to Gagny, nestled in the southwest of the country, within the sub-prefecture of Doba in San-Pédro. Navigating rugged terrain, we reached a hilltop village where we were greeted by the local community and figures such as Jean Marc N'guessan, coordinator of Ofi’s Cocoa Sustainability Program for Cote d’Ivoire; Kanga Konan Denis from the Coani cooperative; and Germaine Fossou, an advocate for human rights and community development in the cocoa industry. After a warm welcome, we embarked on a guided tour of a nearby cocoa plantation. Before we look at the intricacies of cocoa farming, I'd like to emphasise the sheer intensity of the process. Cultivating cocoa demands hard manual labour and constant attention. With cocoa trees bearing fruit throughout the year, great care and consistent harvesting are essential. Next time you indulge in a chocolate bar or milkshake, consider the journey that bean has taken.

On the cocoa farm

As the proverb goes, giving someone a fish feeds them for a day, while teaching them to fish ensures sustenance for a lifetime. This timeless wisdom rings true in farming as well, where success hinges on mastering the best practices.

During our tour of the nearby cocoa farm, led by Ouedraogo Abdramane, a cocoa farmer and member of the Coani Co-op, we gain insight into the multifaceted process of cocoa cultivation. The cocoa harvest spans from October to September, marked by distinct harvest periods: the primary harvest stretching from October to March, followed by a mid-crop from April to June, and a smaller yield from July to September.

Abdramane explained the myriad factors at play in cocoa farming. Across these 2.5 hectares of land, he emphasised the pivotal role of pruning, vital for ensuring optimal sunlight and airflow to the cocoa plants. The team uses specific tools depending on the type of branch they are cutting.

Additionally, he underscores the significance of composting, revealing the farmers' hand-crafted recipe for producing their own organic fertiliser.

The perfect recipe

The farmers craft a natural fertiliser from a blend of decomposed food, water, wood ashes and fresh leaves, all readily available waste materials. This concoction, cost-free to produce, is then spread around the cocoa plants to supply the essential nutrients for growth.

First, they incorporate rotten cocoa pods into the mixture, followed by a layer of fresh leaves. Next, they collect chicken excrement to top it off. Wood ashes join the mix, followed by soil from the local surroundings and water. This process repeats several times until a substantial pile forms. A sheet is placed atop the heap to maintain warmth, sealed tightly to exclude air. After a week, the farmers assess progress by probing the soil with a stick; if it's warm, they know it's advancing well. Two weeks later, they inspect again, mixing the compost and setting aside a portion to begin a new pile.

In total, the process spans three months until the fertiliser reaches readiness.

Additionally, insects play a crucial role in expediting the process by enhancing soil structure, enriching it with nutrients and promoting aeration.

Abdramane's connection to this farm runs deep; it's been in his family for generations and was gifted to him by his father. Reflecting on the past, he recalls a time devoid of shade trees, cooperative assistance and knowledge of essential techniques. Grateful for Ofi's support, Abdramane expressed deep appreciation for the company’s role in not only sustaining his farm but also in enriching the land, ensuring it is capable of yielding abundant, high-quality cocoa.

Harvest time

Once the pods bearing cocoa beans ripen, they are delicately cut from the trees and opened to extract the moist beans. The white flesh surrounding the beans can also be consumed, and features a surprisingly sweet, delicate and refreshing taste. With precision, farmers employ well-sharpened blades to cleanly sever the stalks or wield pruning hook tools for those perched high. The placenta is then removed from the bean. Once harvested, the pods are opened within a week to ten days. Whether split in the plantation or transported to a fermenter, the discarded husks find purpose in enriching the soil. While traditional methods involve manual labour with wooden clubs or machetes, modern machinery is sparingly employed. At this farm, the cocoa beans are laid out on huge banana leaves to undergo the drying process. A bucket placed underneath the leaf collects the cocoa water, earmarked for another purpose: cocoa liquor production!

Fermentation is a pivotal stage where beans are piled together to foster microbial growth. Yeasts and insects initiate the fermentation process, converting sugars to ethanol, which eventually evolves into lactic acid or acetic acid. This is where the banana leaves prove their worth: Abdramane explained how the leaves are carefully turned upwards to unveil the fungus thriving beneath, which helps with the fermentation process.

As temperatures rise, the distinctive flavours and colours synonymous with chocolate begin to emerge. Depending on the bean type, fermentation can span from 2-5 days, each crucial for flavour development.

Following fermentation, beans undergo a drying process to reduce moisture content and enhance flavour – they must have expelled a certain amount of humidity before they reach the processing facility. Sun drying or artificial drying methods are employed, ensuring a delicate balance to prevent off-flavours while maintaining optimal bean quality.

Change and adapt

For the farmers, climate change has introduced uncertainty into their preparations. “Previously, we could predict when the rains would come and when the dry season would begin,” said Abdramane. “Now, we face situations where rainfall may not occur when needed, or there might be excessive rain, leading to difficulties in drying cocoa beans due to reduced temperatures.” The process involves several complex steps: rainfall is essential for crop growth; hot air is necessary for drying the beans, and dry, hot weather is crucial for the fermentation process. And so, climate is intrinsic to every part of the production process.

Co-op life: Village meeting

After concluding our tour of the cocoa farm, we return to the village to convene with the local Coani cooperative. Founded in 2013, the Coani co-op initially comprised 124 member farmers. Fast forward to the present, and its membership has swelled to 484, with 450 men to 34 women. Guiding its operations are seven dedicated individuals serving on the board of directors.

Since 2018, Coani has proudly held Rainforest Alliance certification, signifying its commitment to sustainable practices. Furthermore, it has collaborated with Ofi since the same year, fostering a partnership aimed at advancing their shared objectives.

Every farmer benefits from access to Ofi's robust traceability applications, particularly the Olam Farmer Information System (OFIS). OFIS serves as a comprehensive survey tool used by Ofi’s field teams to gather data, oversee training initiatives and monitor financing, input distribution and purchases with precision. Leveraging this system, Ofi collects essential data on farmers, facilitating assessments regarding human resources, administrative support, equipment adequacy and tree planting initiatives.

In cases where farms fall short of Ofi's standards, the company provides dedicated support to guide them toward compliance. Through collaborative efforts, Ofi assists farmers in meeting and surpassing the requisite criteria, ensuring alignment with the company's expectations.

Child and forced labour

Child and forced labour remain significant challenges within the cocoa, cashew, coffee and other raw ingredient supply chains, with Cote d’Ivoire particularly affected.

In response, Ofi collaborates closely with Coani and other farmer cooperatives to gather community information, identify issues and determine avenues for support. Germaine Fossou, human rights and community development coordinator for cocoa in Cote d’Ivoire, sheds light on Ofi's ground-level approach.

Initially, they profile both the farm and the farmer, conducting a thorough analysis of the household and assessing the presence of children. They engage directly with each child to ascertain their school attendance and involvement in farm work. Unannounced farm visits by cooperative agents further verify the presence of children and their appropriateness on the premises. In cases of identified child labour, Ofi investigates the nature of the work and its impact on the child's education, demanding remedial action if necessary.

In instances where a significant number of children are found not attending school, Ofi may propose the construction of a nearby school, recognising the heightened vulnerability of girls who often undertake early morning water collection tasks. Remediation efforts may also involve requesting the installation of water pumps in proximity to the community.

Following remediation, Olam conducts follow-ups at three-month and six-month intervals to ensure sustained progress. Once risks are mitigated, the company explores opportunities for further engagement with the community.

Women's group

Following the cooperative meeting, we are introduced to the women of the community who are active participants in the Village Savings & Loans Association (VSLA). This group convenes weekly, with each member contributing funds to a collective savings pot for additional support and events. After three months of membership, a woman becomes eligible to request a loan, which can exceed her initial contribution and is repaid with interest. Currently comprising 30 members, the VSLA empowers women to pursue various ventures with financial backing. One member shared her experience of using a loan to finance her child's education and invest in a rice farm. Funds can also be allocated towards training initiatives, with 16 programmes available to enhance entrepreneurial skills. Another member received a loan to establish a hair salon, while many others venture into vegetable cultivation, including onions, cassava and eggplant.

Cultural shifts

As the day ended, a thought stuck with me. One of the most significant transformations impacting rural life in Cote d'Ivoire is the increasing financial independence of women. Ofi’s Fossou acknowledged this shift, recognising potential challenges within households where conflicts may arise due to women's newfound earning capacity. To address such issues, Fossou suggests that conflict resolution training may be necessary to foster harmonious relationships in households experiencing these adjustments.

Day 5: San-Pédro cocoa processing facility

As our final day begins, we tie up loose ends by exploring the culminating stages of cocoa production. Seraphin Amichia, processing manager at Ofi's cocoa processing factory in San-Pédro, provides an overview of the cocoa production process, which unfolds as follows:

Harvesting: cocoa pods are harvested from cocoa trees when they are ripe. Workers use machetes or specialised tools to carefully cut the pods from the trees.

Fermentation: the harvested cocoa pods are opened, and the cocoa beans and pulp inside are extracted. The beans are then placed in large containers or heaps to ferment. During fermentation, naturally occurring yeasts and bacteria break down the sugars in the pulp, generating heat and causing chemical changes in the beans. This process is crucial for developing the flavor precursors in the cocoa beans.

Drying: after fermentation, the cocoa beans are spread out to dry. This can be done by laying them in the sun on large mats or drying racks, or by using specialised drying equipment. Proper drying is essential to reduce the moisture content of the beans and prevent mould growth.

Roasting: once dried, the cocoa beans are roasted to develop their flavour further. Roasting also helps to remove any remaining moisture and sterilises the beans. The temperature and duration of roasting can vary depending on the desired flavour profile.

Cracking and winnowing: after roasting, the cocoa beans are cracked open to separate the outer shell (husk) from the inner nib (the meat of the cocoa bean). This process is called winnowing. The husks are usually removed, leaving behind the cocoa nibs.

Grinding: the cocoa nibs are ground into a thick paste called cocoa liquor or cocoa mass. The grinding process generates heat, which liquefies the cocoa butter present in the nibs, resulting in liquid chocolate.

Refining: the cocoa liquor is further processed to reduce particle size and improve texture. This is typically done in a series of refining machines, which grind the chocolate until it reaches the desired smoothness.

Conching: conching is a crucial step in chocolate making that involves kneading and aerating the chocolate to develop its flavour and texture. This process can take anywhere from a few hours to several days, depending on the desired characteristics of the chocolate.

Tempering: finally, the chocolate is tempered to ensure proper crystallisation of the cocoa butter, which gives chocolate its glossy appearance and smooth texture. Tempering involves carefully heating and cooling the chocolate to specific temperatures while stirring it continuously.

Cocoa mass (cocoa liquor) is the combination of cocoa solids and cocoa butter obtained from grinding cocoa beans, cocoa cake is the solid material remaining after pressing cocoa mass to extract cocoa butter, and cocoa butter is the edible fat extracted from cocoa beans, prized for its role in chocolate making and various other applications.

Walking through the factory, the aroma is incredible! Sweet, warm chocolate notes waft through the air – it's a real-life Willy Wonka experience! Though I must admit, experiencing this every day might alter my perception! Our explorations of Cote d’Ivoire unveiled the intricate journey behind cocoa, coffee and cashew production. From the warm welcome by community leaders to the enlightening insights shared by local farmers, our journey has been informative, eye-opening and loads of fun.

Ultimately, our time here celebrates the symbiotic relationship between tradition and progress, community and industry, inviting us to appreciate not just the flavours and applications of these raw ingredients, but the narratives of resilience and stewardship they encapsulate.

.jpg)